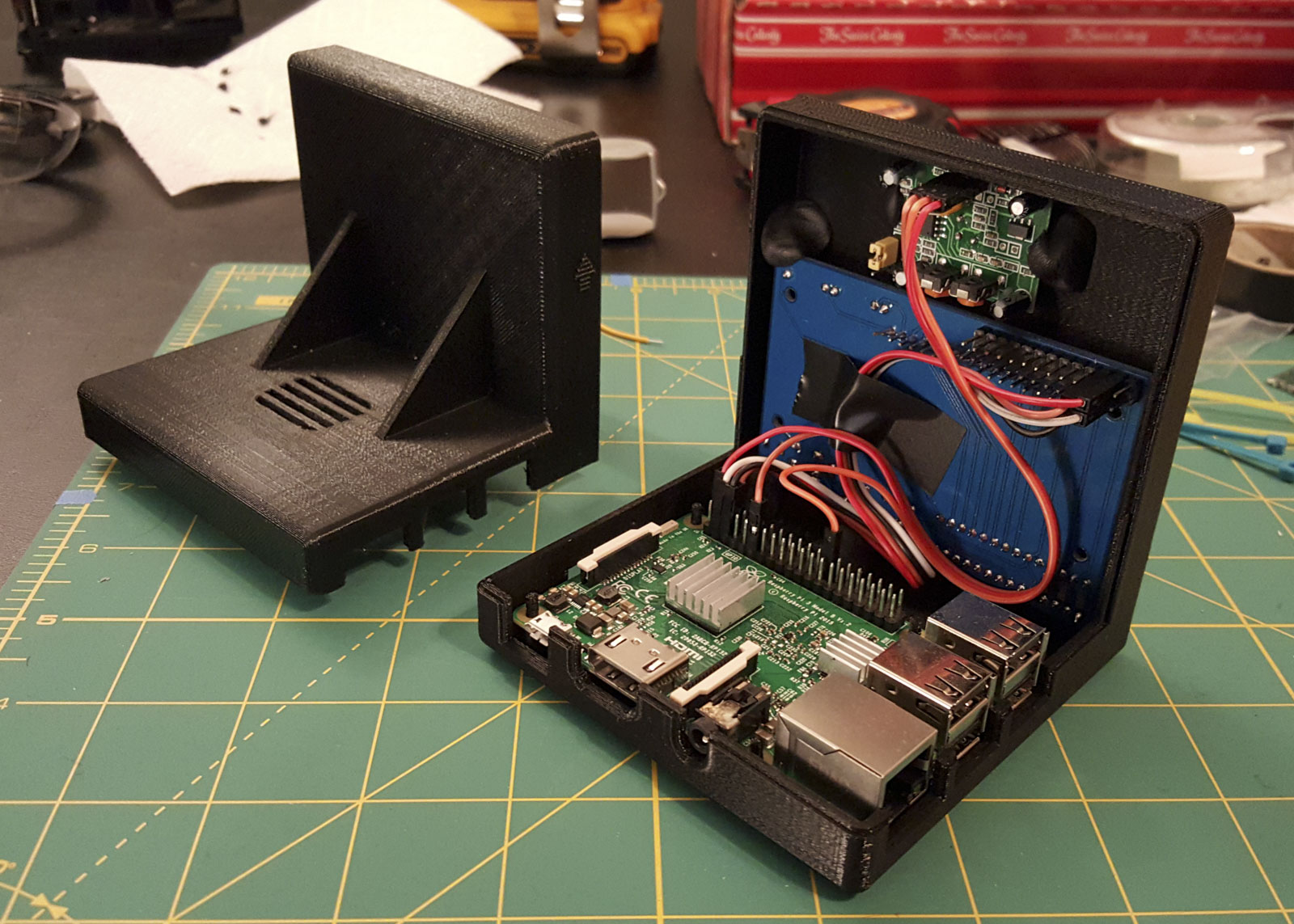

I built this project a few years back and it has become crucial to my daily workflow.

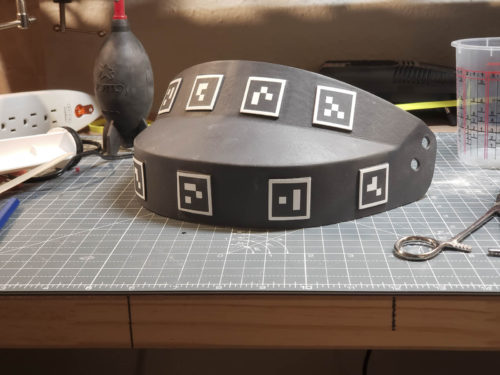

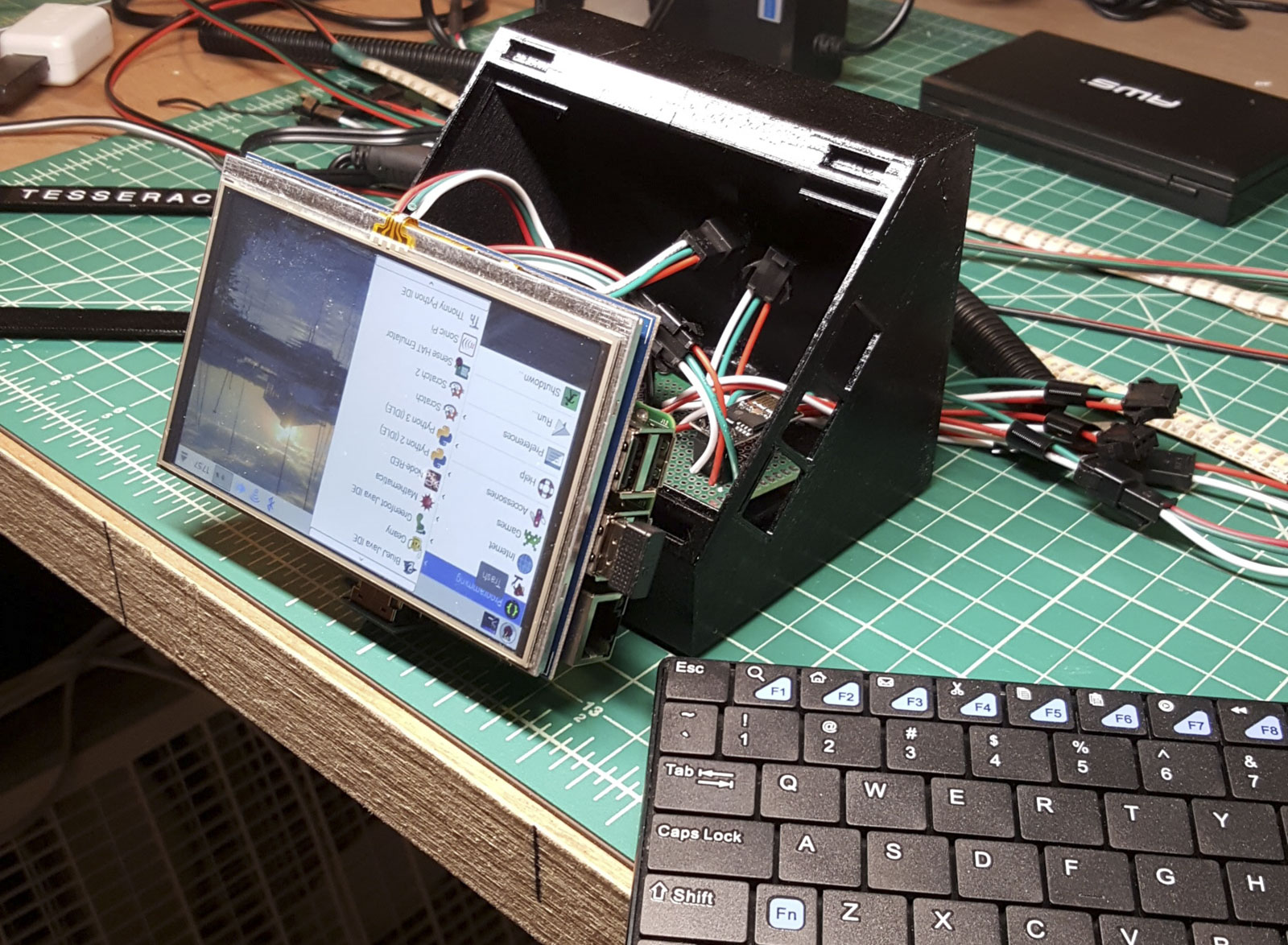

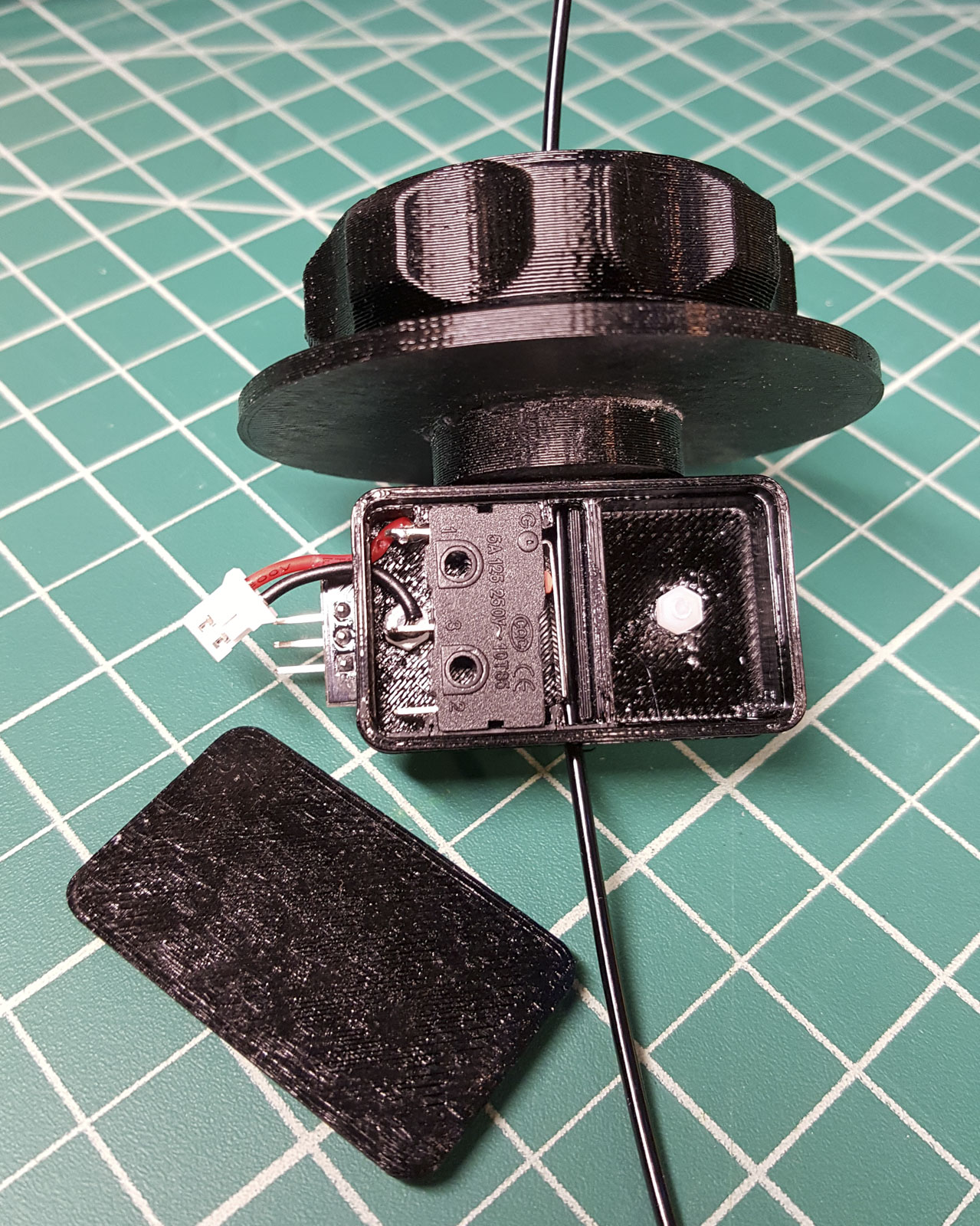

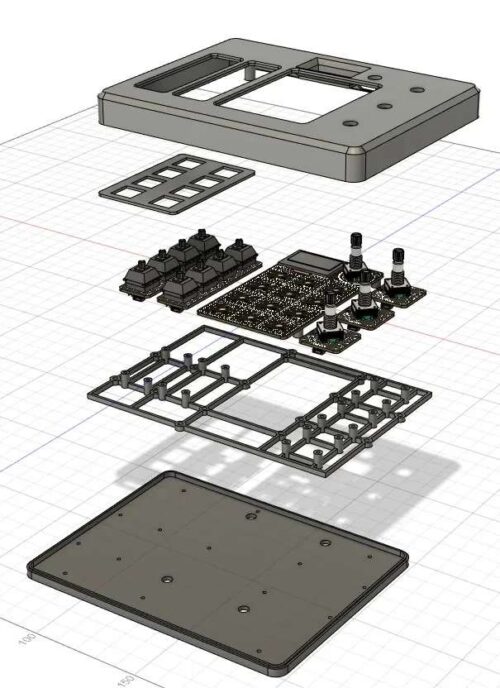

It’s based on the Adafruit MacroPad which I’ve extended with 2 1×4 Stemma Qt NeoKeys and 3 Stemma Qt Rotary Encoders.

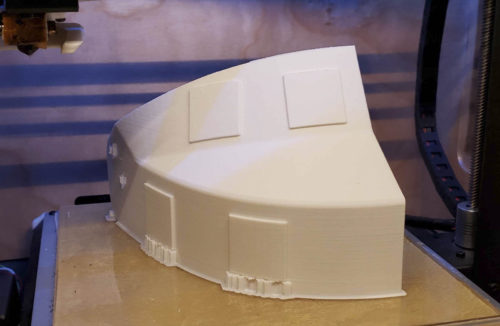

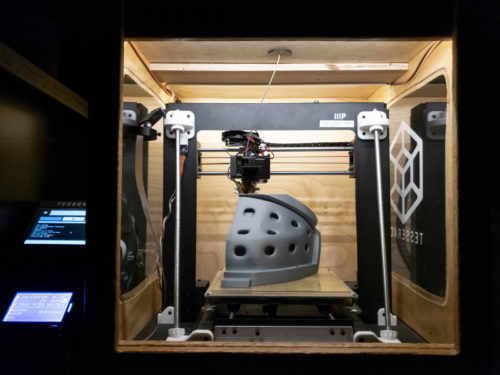

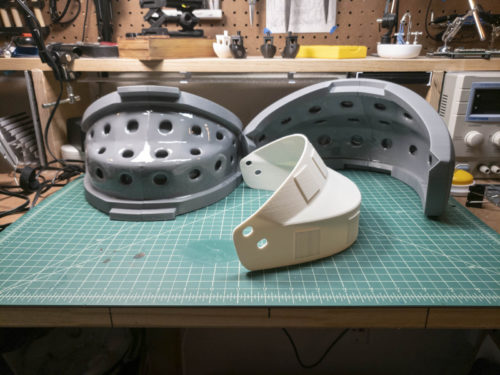

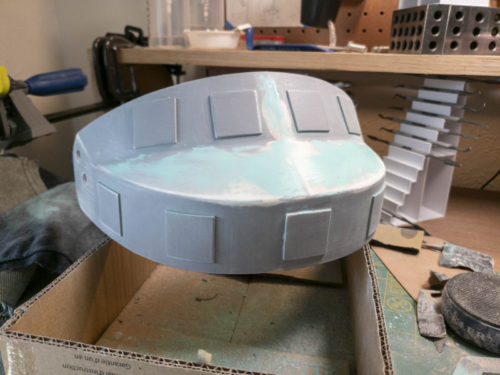

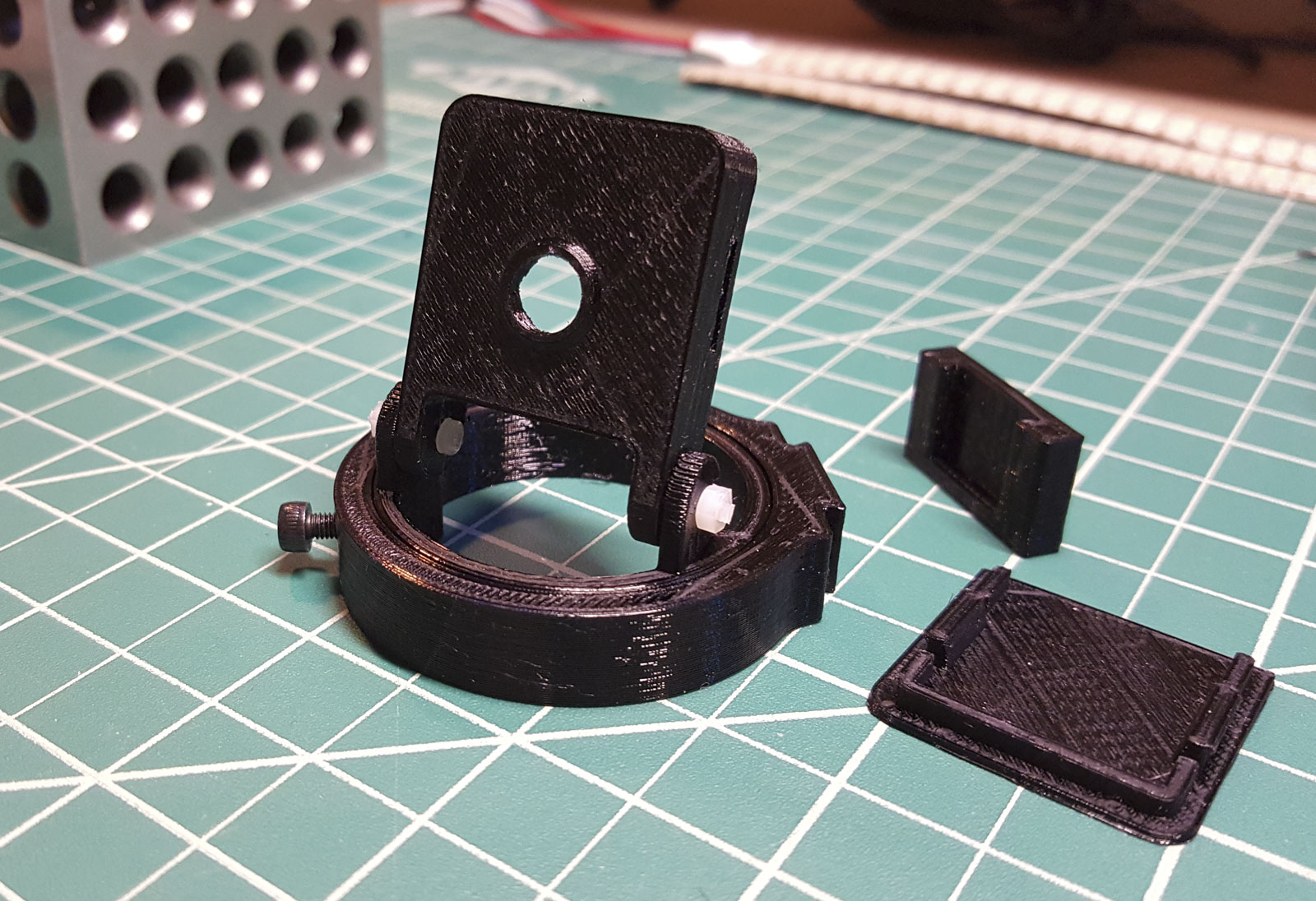

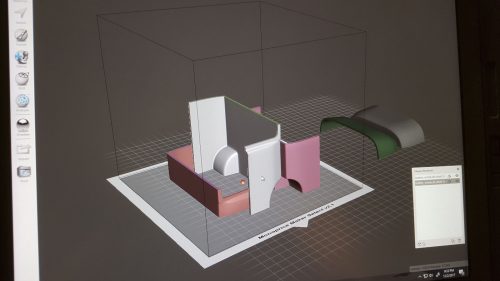

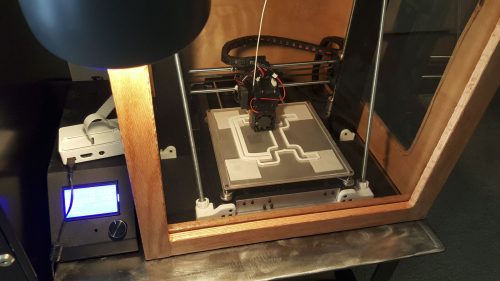

You can find the print files HERE

If you do build one, I encourage you to write your own code for it, as it is a fantastic learning experience, which you can get started on from reading their well written guide Here.

I will provide a link to my code, which is heavily based off the Adafruit example, but with a few additions to handle the extra hardware. https://github.com/pixelpushinfreak/key_tickler_macro_pad

The only additional hardware needed are a bunch of pan head, #2-28, 5/16″ plastic screws.

Let me know if you build one or do any cool remixes! I’ve had ideas to extend the code for a while now, but just can’t find the time to get back to it, not to mention that it’s been working great as it is :)