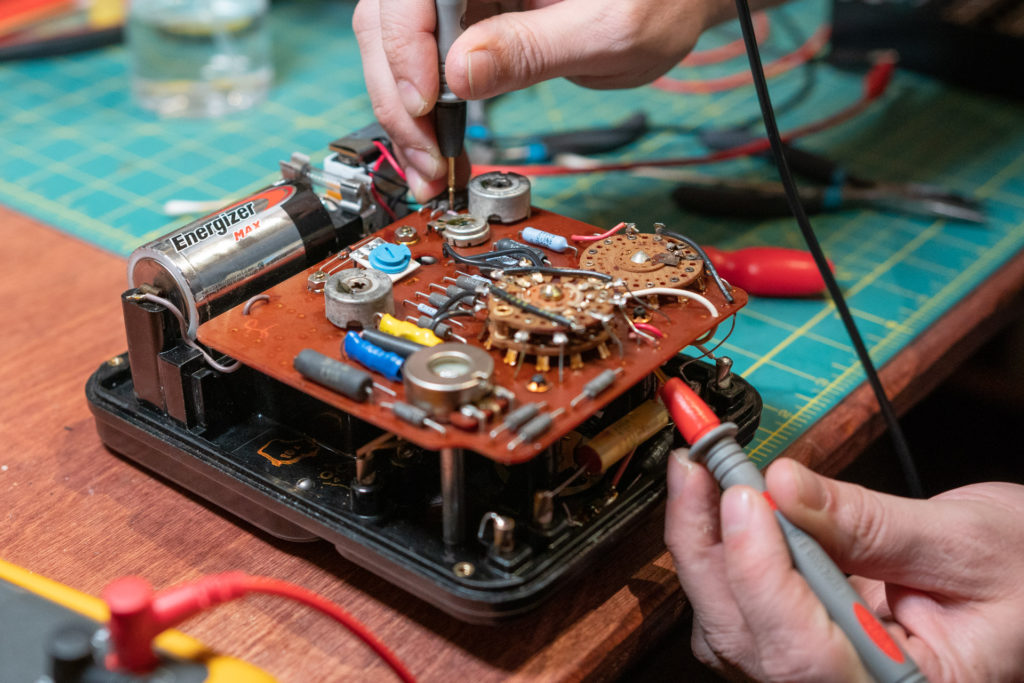

I bought this and I couldn’t get it calibrated. If I calibrated the voltage to 1.5 V at full scale and then switched to any other scale, the readings were very far off. Sometimes more than 10%.

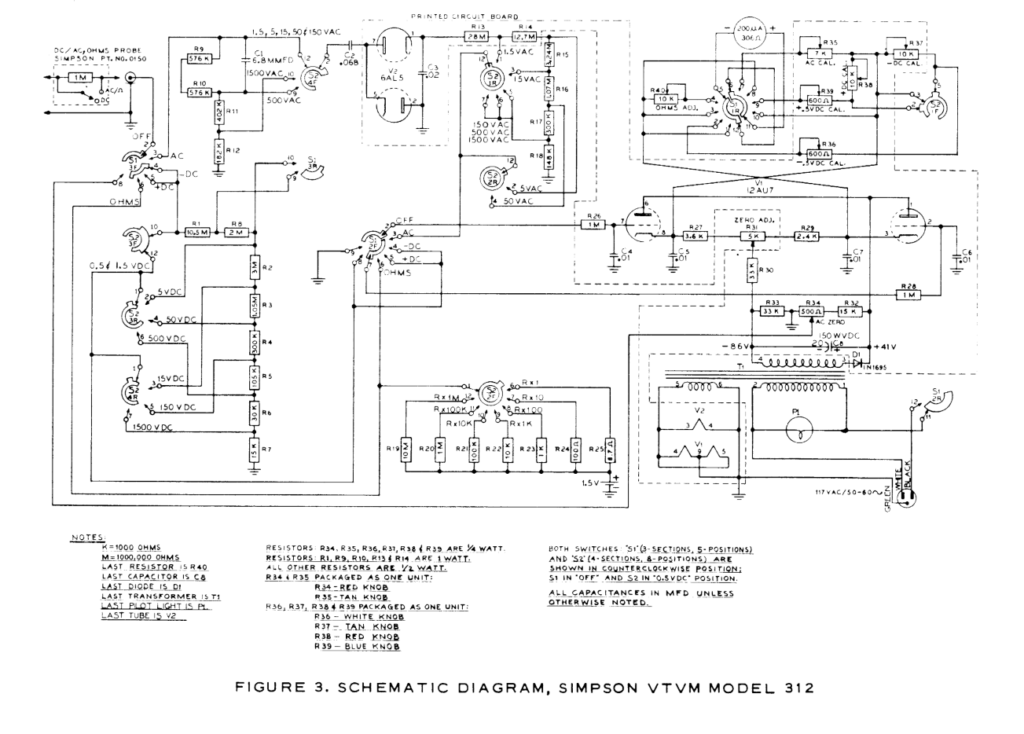

Here is the schematic for the unit

When I measured the precision resistors inside the unit, they were not precise. Over the last fifty years I guess these drifted some. More than half of the resistors were outside their 1% tolerance.

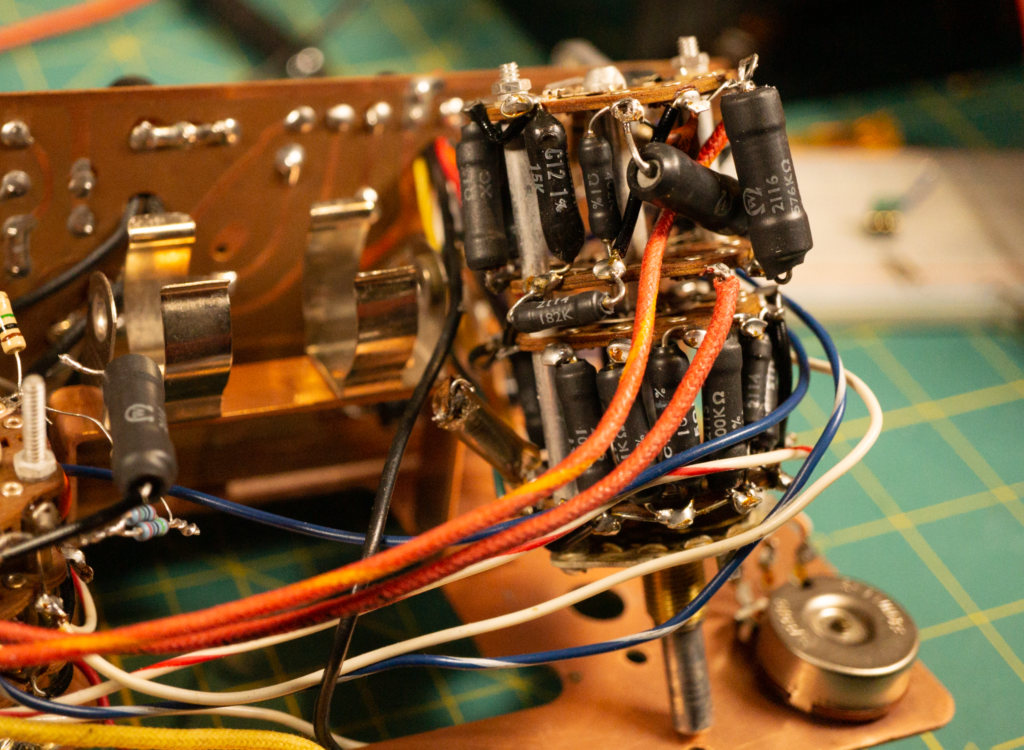

These are the resistors causing trouble

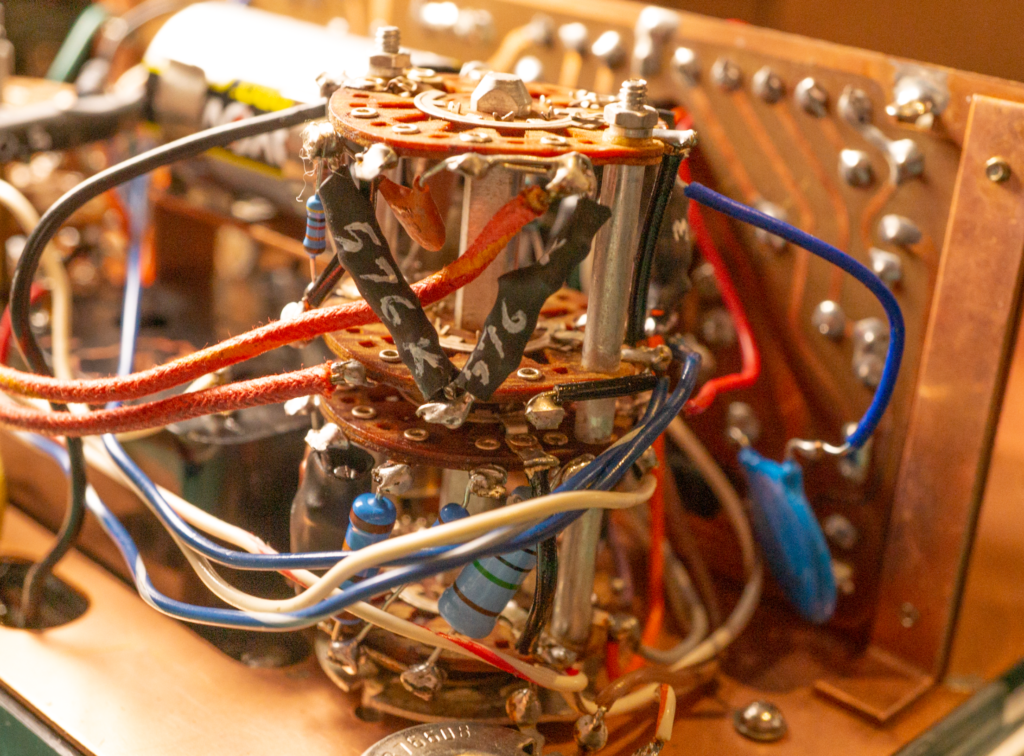

To fix the problem I bought a bunch of metal film resistors that were as close the to correct values as I could. When I couldn’t get exact matches, I made my own by combining different values. All the resistors values. All resistors are now within a 0.5% tolerance.

Here is the unit with the new resistors and some of the ugly ones I made.

This process took a while. After I made all the high precision resistors, I clipped each of the old resistors out and replaced them one at a time.

Here are the old resistors. After checking them only about half of them were within the 1% tolerance they should have been. Some of the worst were off by as much as 10%.

After changing all the resistors, the 312 VTVM held its calibration beautifully. All of the full scale values stayed spot on.

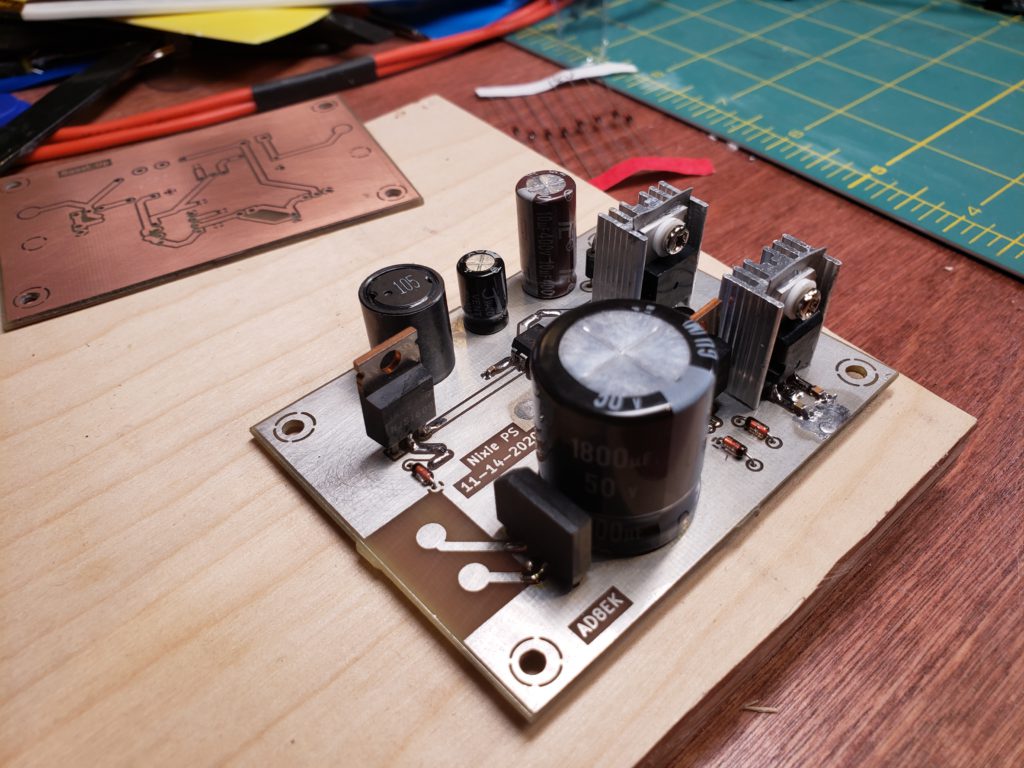

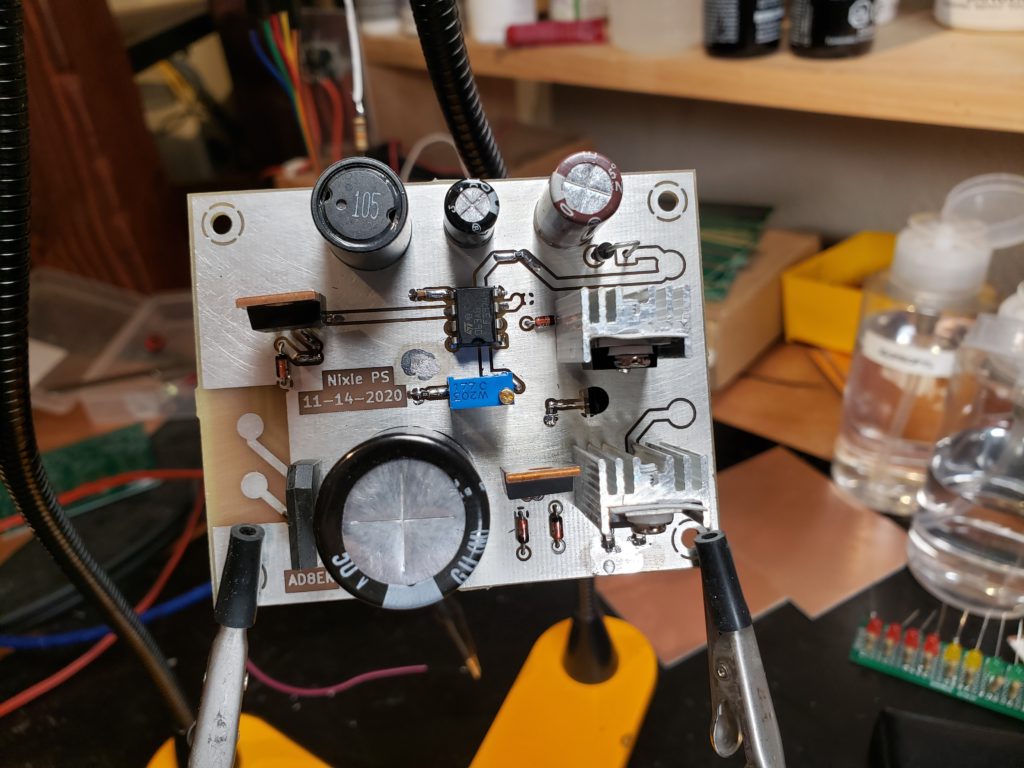

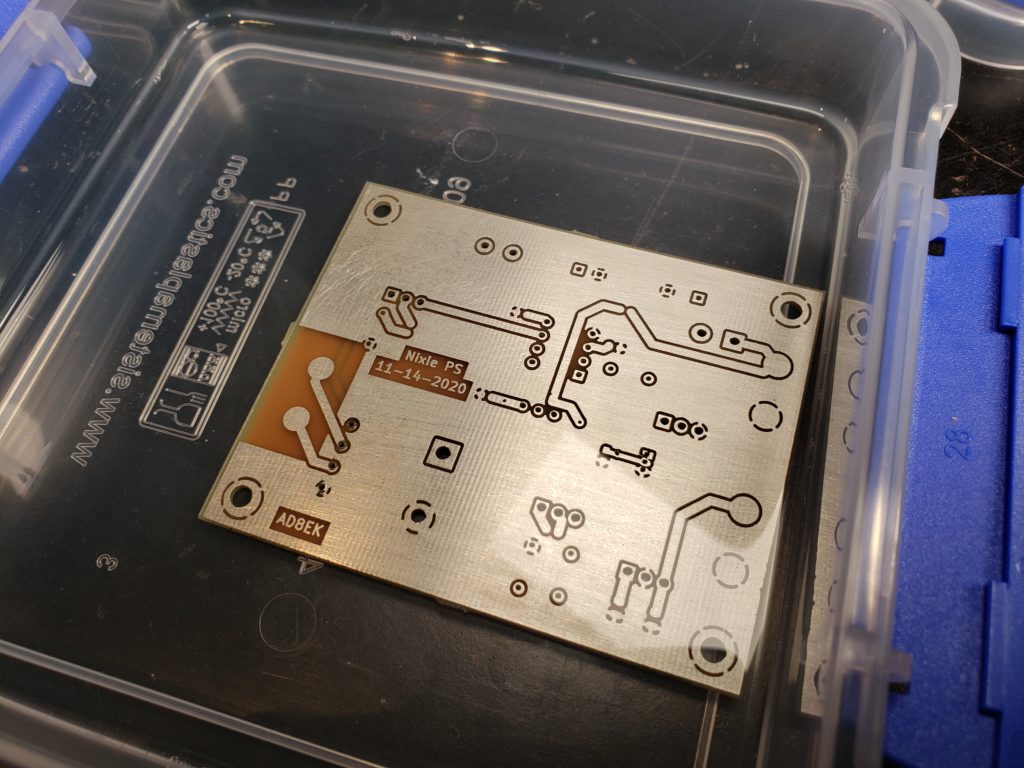

If you have the opinion that you should just send your boards to China to have them made, I get it. But, I like these.

I added to my process a CNC machine. I drill all the holes and cut out the board with the CNC machine. I then use the transfer toner method and etch the board.

The board is a boost converter I’ve been playing with. I’m playing with Nixies and wanted something kinda stout to supply current for up to eight bulbs. Works good too.

This is my temporary lab in Colorado. Just moved back from Ohio and waiting to close on our house. This setup is in my parents back yard…

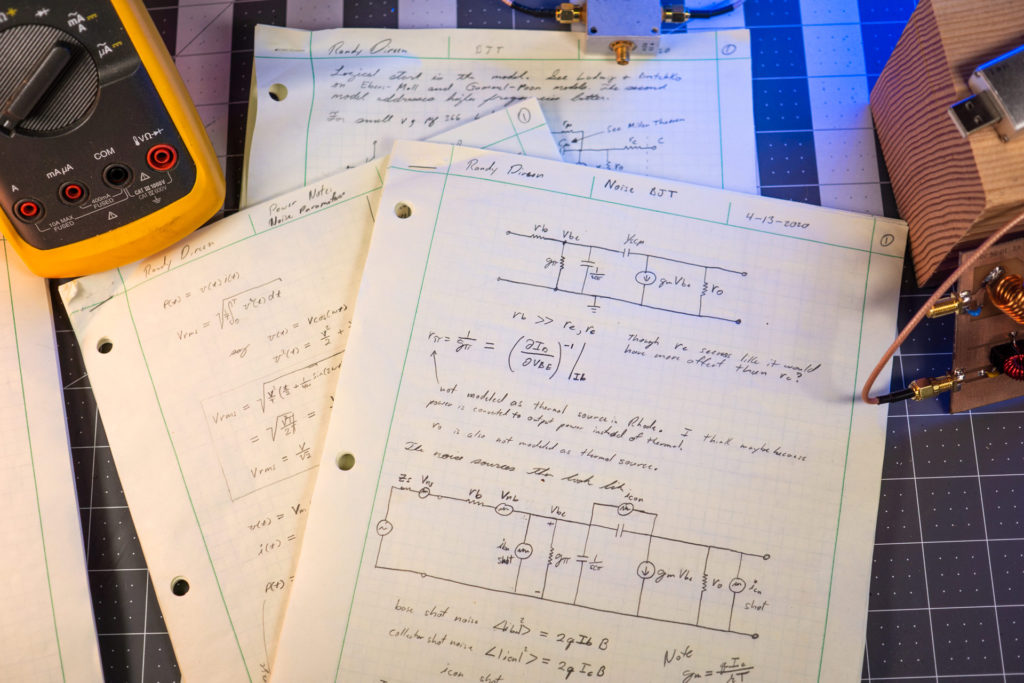

In my down time I’m studying noise in BJTs. I have a handful of papers I’m using for reference (TODO: put references in).

My wife helped me write a bunch of MATLAB routines to work with covariance matrices. I now how a pretty powerful setup to simulate RF noise parameters. I’ll report on those here soon.

I built an electronic speed controller (ESC) and I’m in the process of setting up a bench to measure it. This post has a few pictures of my setup and a little description of my ESC.

The above image answers the question: Do I have enough Fluke meters? No, I need more. From left to right they measure

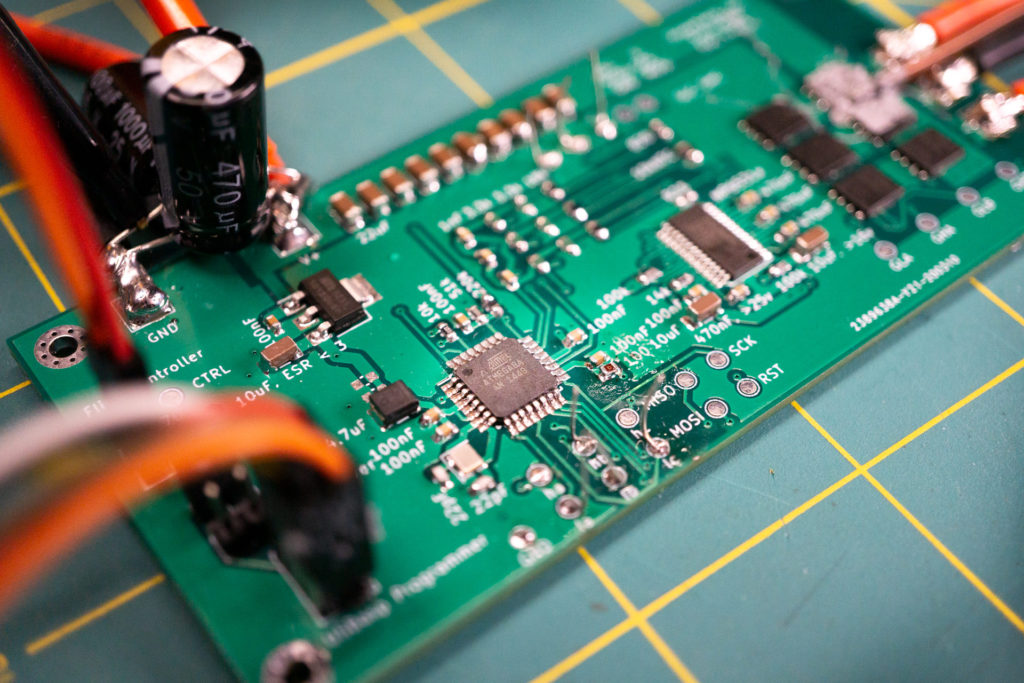

Here is the demo ESC board I designed and soldered together

If you know quadcopters, or other multirotor UAVs, you’ll notice this design is huge. It will get smaller in the next rev, but I wanted a board with a bunch of test points and additional components. This way I can balance everything out before I make things smaller.

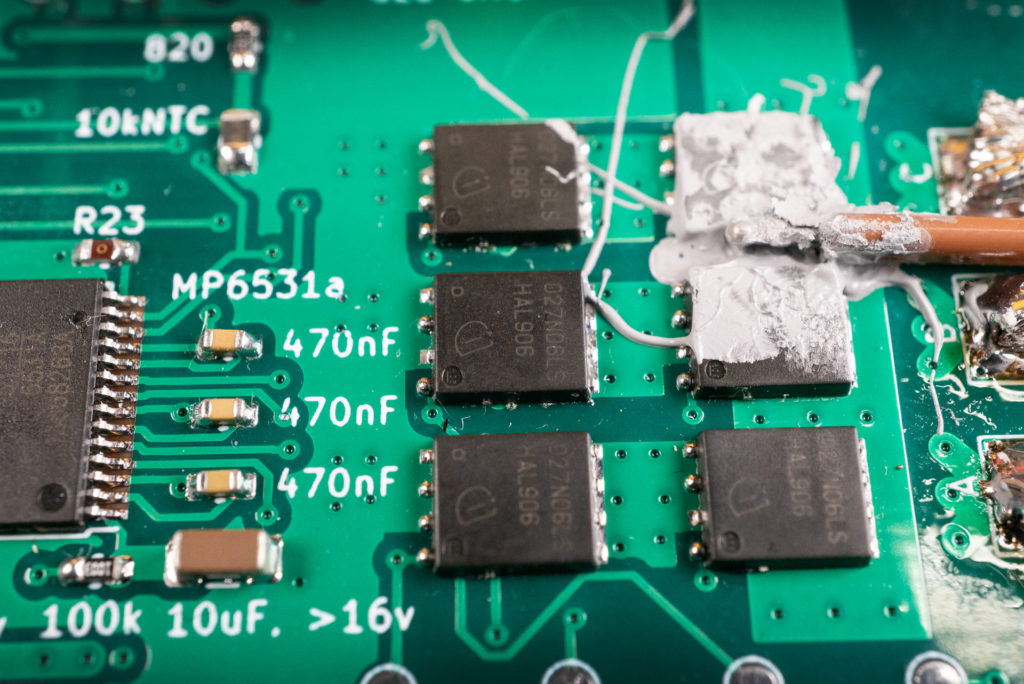

The MOSFETs are Infineon BSC027N06LS5s. I spent some time looking for low resistance, high current transistors for the project. Specifically, I wanted a high current rating without having to dip the transistors in liquid nitrogen. Infineon specifies that their transistors can handle 23 Amps in ambient conditions. I’ll have to do some tests to see what I can get out of them. I do plan on putting a heat sink on them, but I’ll play around with them a little in the air first.

The goo you see in the upper right is slathered around my type-k temperature probe, which is connected to my Fluke 289.

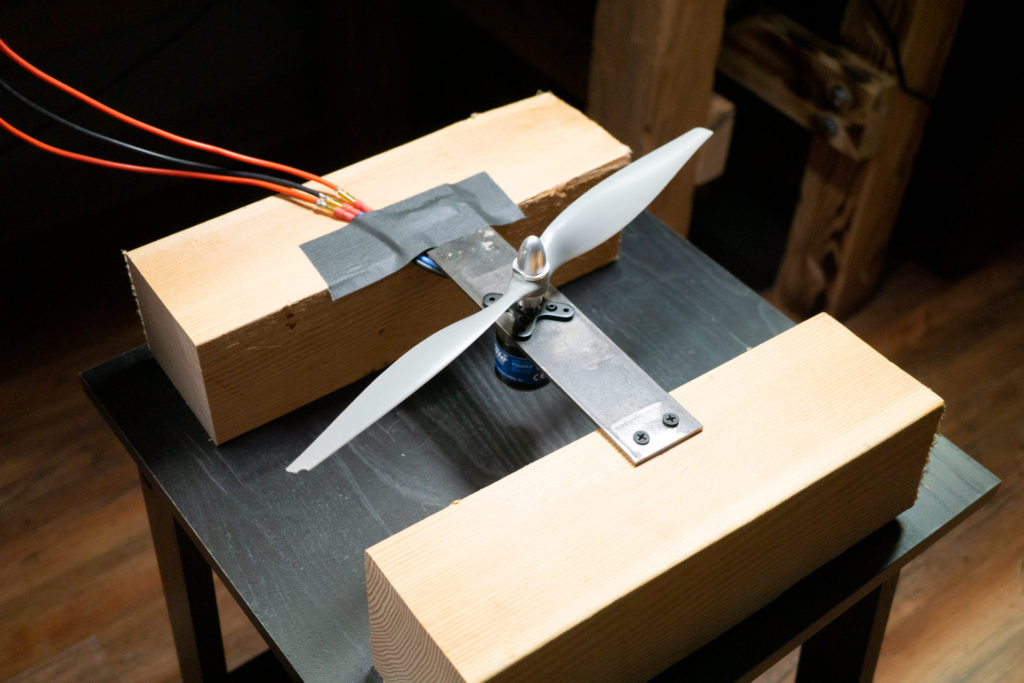

I don’t know much about motors so I went to the hobby store and found something that looked fairly stout. I wanted a setup that would pull on the transistors pretty hard. The image below is of the E-flight EFLM4025C with a 14″ blade attached. I don’t think you would usually use these in a multirotor.

Initial tests wore out my 5 Amp power supply quickly. I anticipated it would, so I bought a couple 30 Amp power supplies on Amazon a couple days ago. What I didn’t realize is that the motor would draw so much current at the lowest throttle setting. Right out of the gate it maxed out my little power supply.

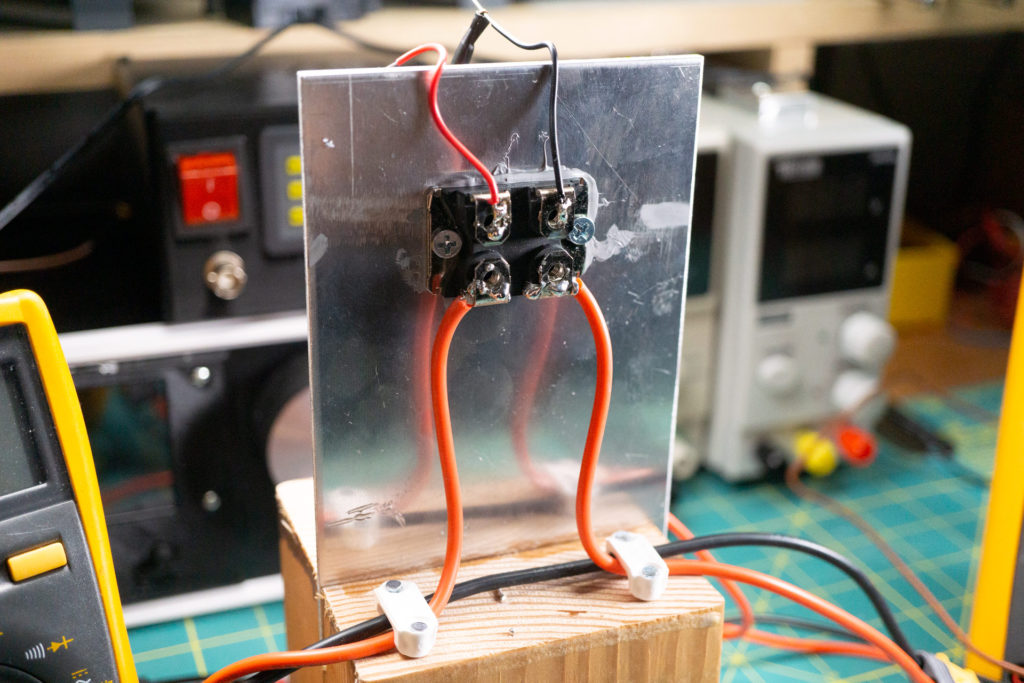

I can’t measure much above 10 Amps directly with my Fluke meters so I bought a sense resistor. The image below shows the resistor attached to a heat sink.

I cut the heat sink and epoxied it to a block of wood. I figured I could use a fan if it started getting too hot. What I forgot though, is that I bought a 0.01 ohm resistor and not a 0.1 ohm. I don’t think it’s gonna get too hot. So now it’s just art.

I’m using BLHeli on an Atmega8 to control the transistors because it’s open source: https://github.com/bitdump/BLHeli. I chose the Atmel processor instead of the SiLabs processor because I already have all the stuff for coding and programming the Atmega8s. I code using Atmel Studio and programming was done using a USBasp dongle. I’ve had to change a few lines of BLHeli code to configure the chip, but it was easy because of the great job those guys did on the code.

If you are interested in making your own ESC there are a few great places to learn. Especially this first reference, which comes from a guy that really seems to like making ESCs:

Thanks for reading this far if you did, I would have just looked at the pictures.

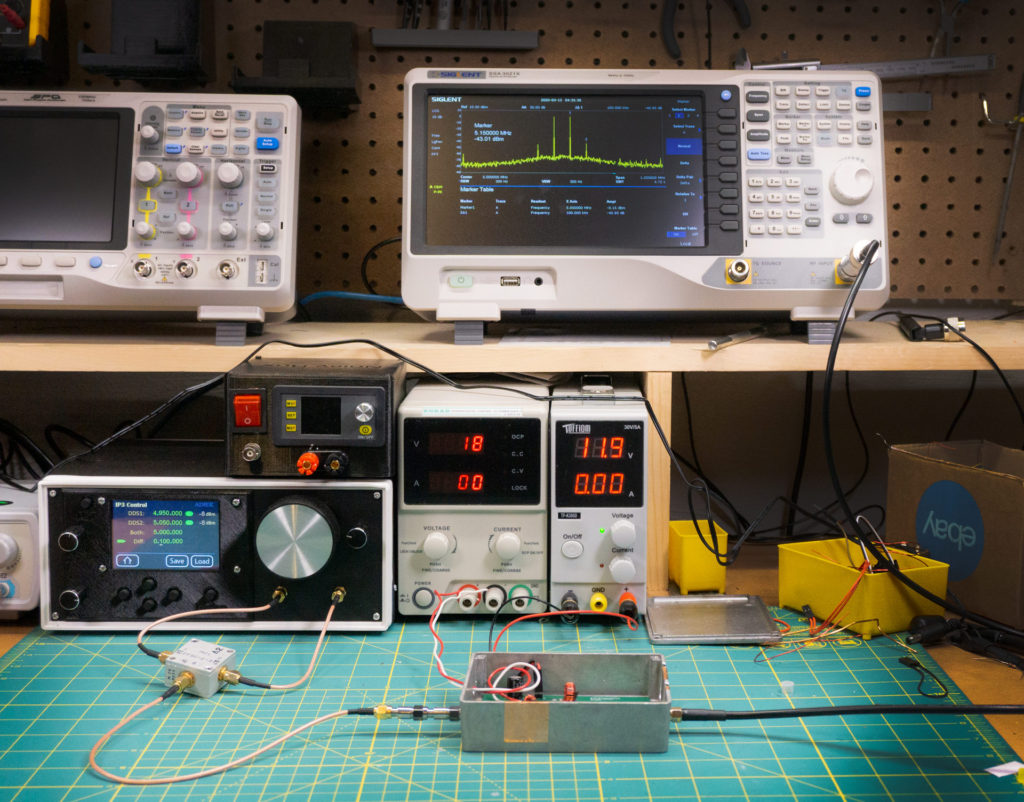

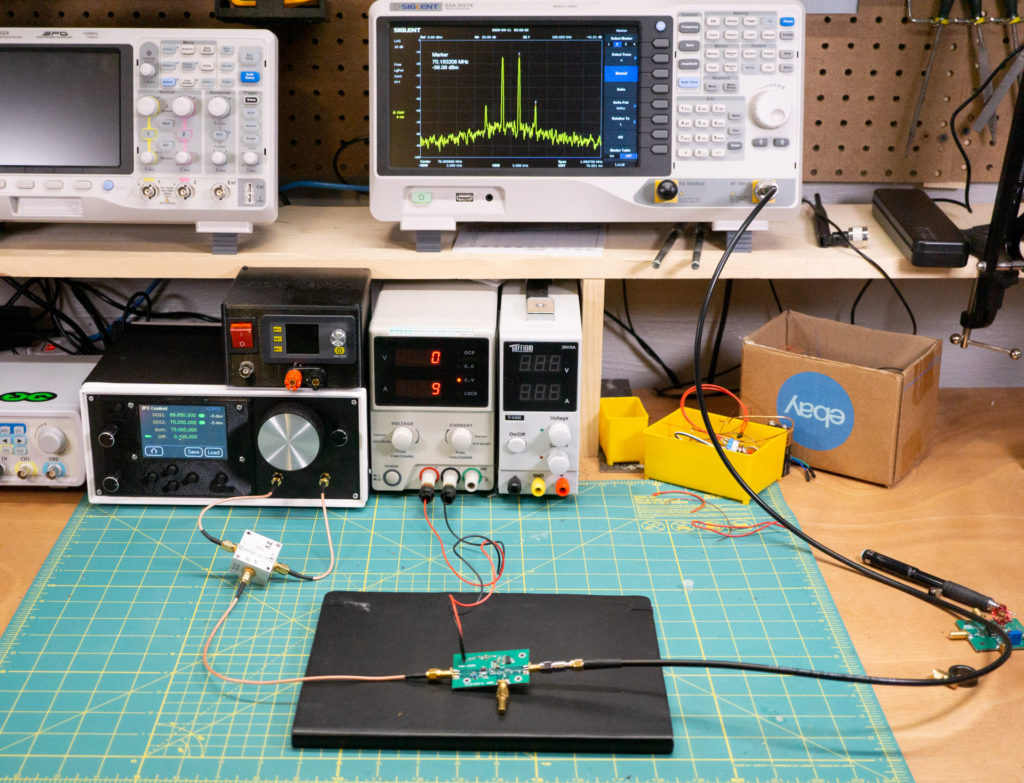

This post is about testing the RF measurement bench I’ve been making. I now have a DIY kit to make noise figure measurements, and a DIY signal generator to make TOI measurements. These along with my KC901V Chinese network analyzer and my Siglent spectrum analyzer provided me with a lot of DIY power.

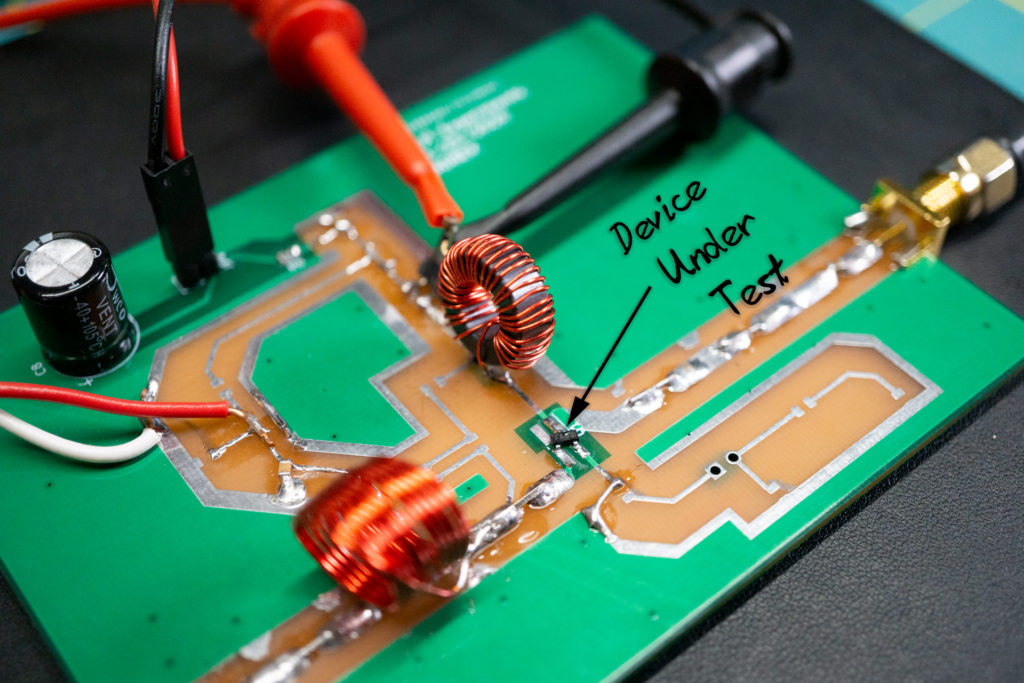

The image above is a board I had made to test common emitter amplifier configurations. It has room for biasing components, degeneration components, a few places for matching components and exposed metal where I can solder in anything else I want. I made 10 of these for about $30 (ordered from JLCPCB). I have a booklet of 0805 resistors and capacitors I bought off of Amazon, as well as a bunch of wire for making inductors.

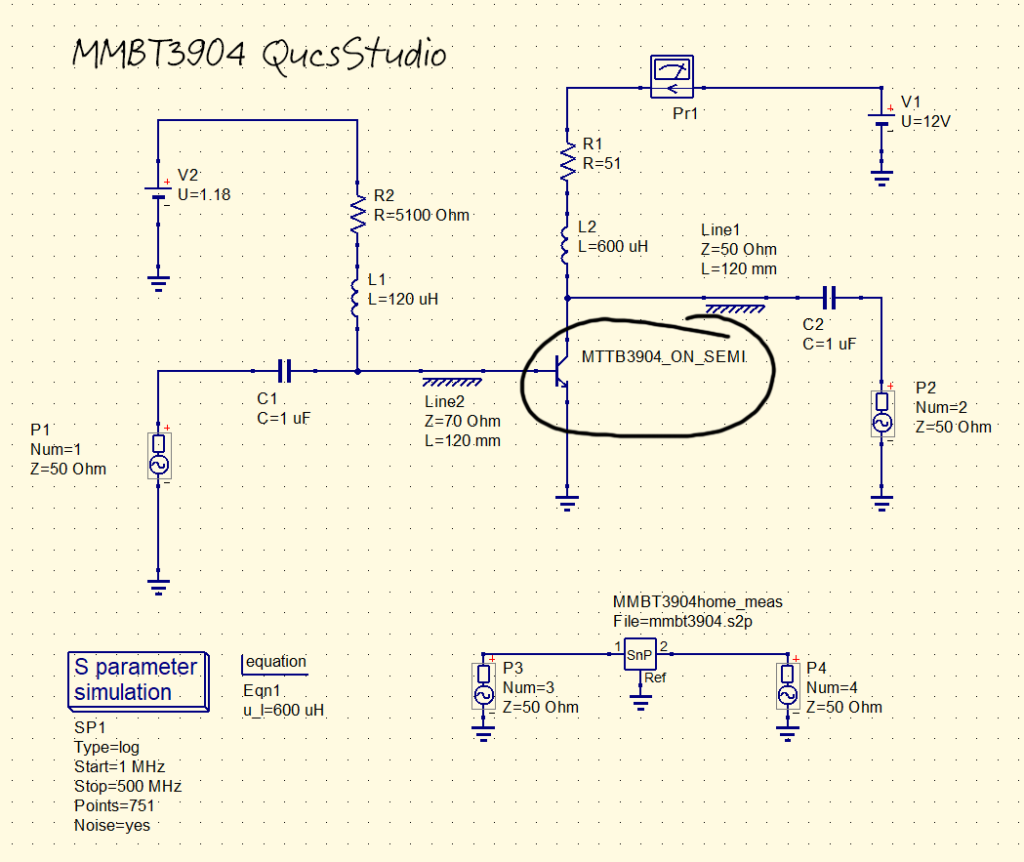

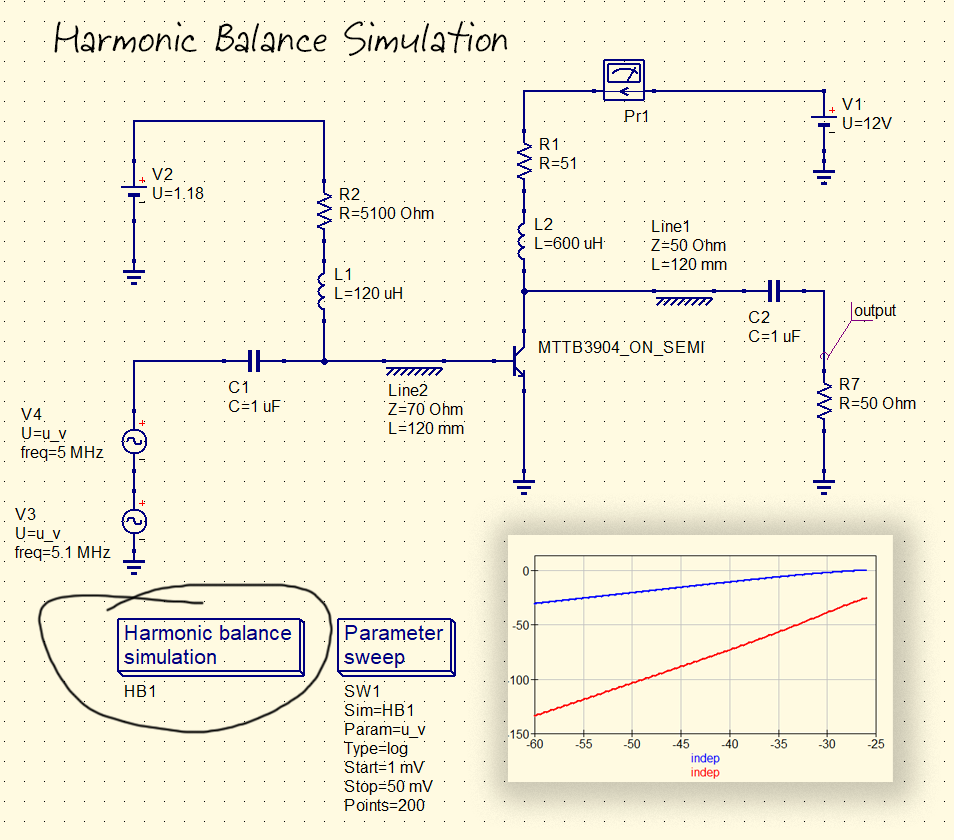

The device I tested is a MMBT3904. No matching, no feedback, no degeneration. Just a couple bias tees and transmission lines. The QucsStudio design shown above provides the values I used for the experiment. I used V2 to test a couple biasing points (20ish mA and 40ish mA).

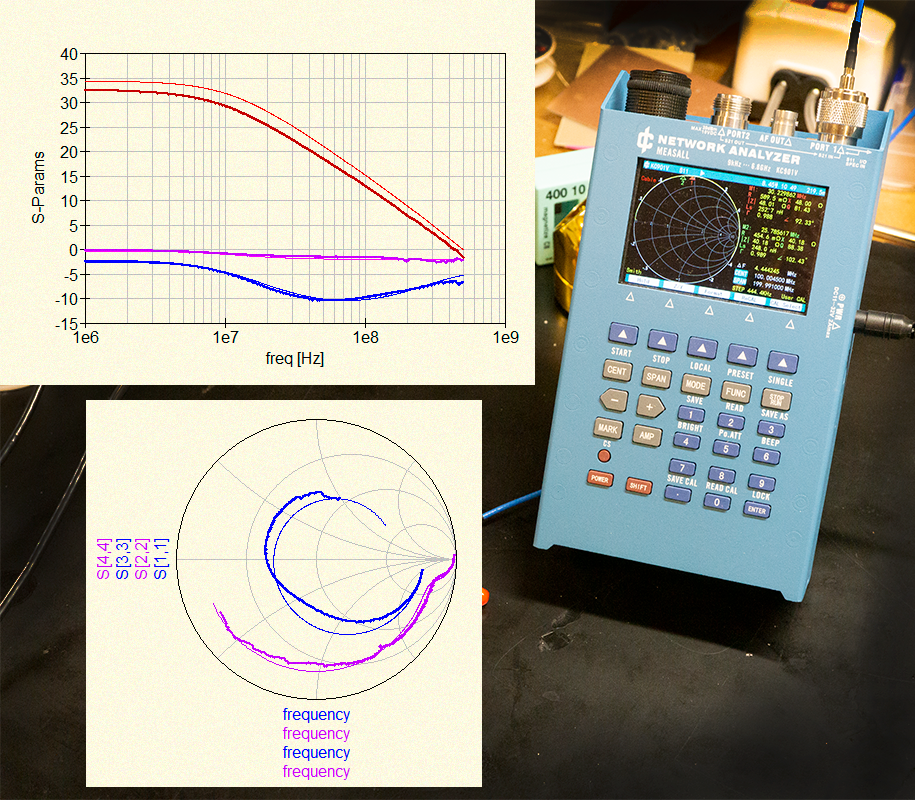

I used my KC901V Chinese network analyzer to measure the S-Parameters and then compared them with simulated results. The thick lines in the plots above are the measurements, and the thin are simulated with QucsStudio. I had to alter RB and CJC in the MMBT3904 Spice model to get the measurement to line up with simulation. Doing so made things line up nicely, but I’m not sure it exactly corresponds with what’s going on. Since I’m just playing, I didn’t spend too much time thinking about it. Good enough for who it’s for.

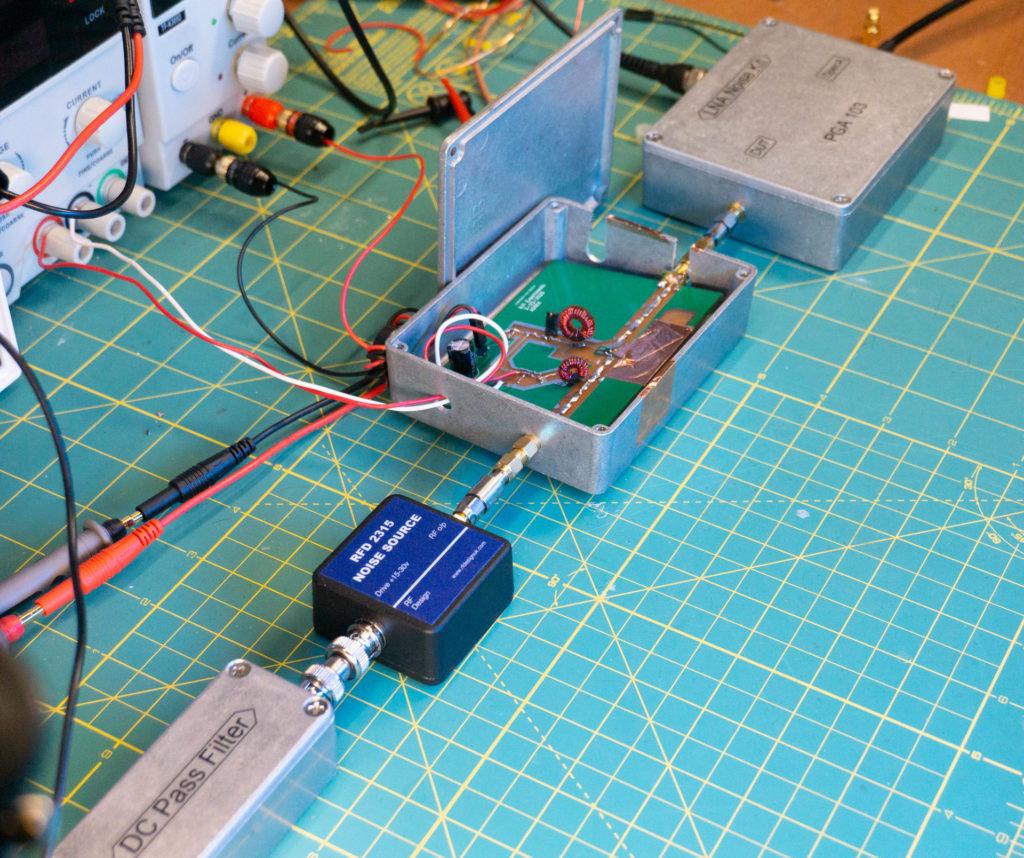

Next I measured noise figure. The setup seen below is the kit I built for measuring noise with my Siglent spectrum analyzer. At the bottom of the image you see the calibrated noise source from RF Design. It has an ENR of 15 dB and is calibrated from 10 MHz to 1420 MHz. The top of the screen shows a box containing a 25 dBish LNA to set the noise floor and add some gain going into the spectrum analyzer.

When I made the common emitter circuit board, I designed it so I could easily stuff it into the aluminum box shown above. I buy these from Amazon and like to use them for RF project boxes. For noise figure measurements you really need to do something like this; otherwise, environmental noise easily corrupts the measurement.

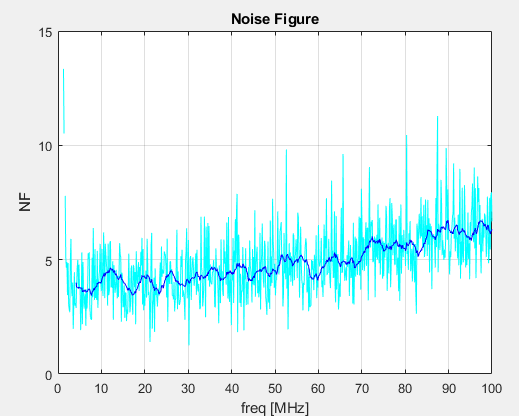

For the measurement I use MATLAB to control the spectrum analyzer. MATLAB places the analyzer into the correct state and collects data over the limits I specify. Using the ENR of the noise source, I calculate noise figure via the Y-Factor method. I’ve had to spend time getting this right, but I believe the figure above is correct to within 1 dB… or two. There are many places where uncertainties creep into these measurements and I’m still working on understanding the limits of this setup. But, the datasheet for the MMBT3904 does say its noise figure is 5 dB. It does not specify the minimum NF, so I’m not sure how small it can be. (Stay tuned in future posts where I make a noise figure parameters measurement DIY kit 😐 .)

The final measurement I made was of the TOI using my new signal generator. I built this box and wrote about it in a previous post. The box can be seen in the lower left side of the image below. I made it so I could easily generate a couple tones for doing IP3 measurements. (It also does other stuff.)

The OIP3 value I measured was about 21 dB. To verify, I used Harmonic Balance analysis in QucsStudio:

Aaaand the result is OIP3 = 20.9 dB. Usually when simulation and measurement are this close I’m more suspicious than if the results were wildly off. But, since this was just an exercise in testing out my RF measurement bench, I’m going to call it a day.

Right now I’m really happy with this setup. I’ll continue ironing out problems and reducing uncertainties as I work on more projects.

73,

AD8EK

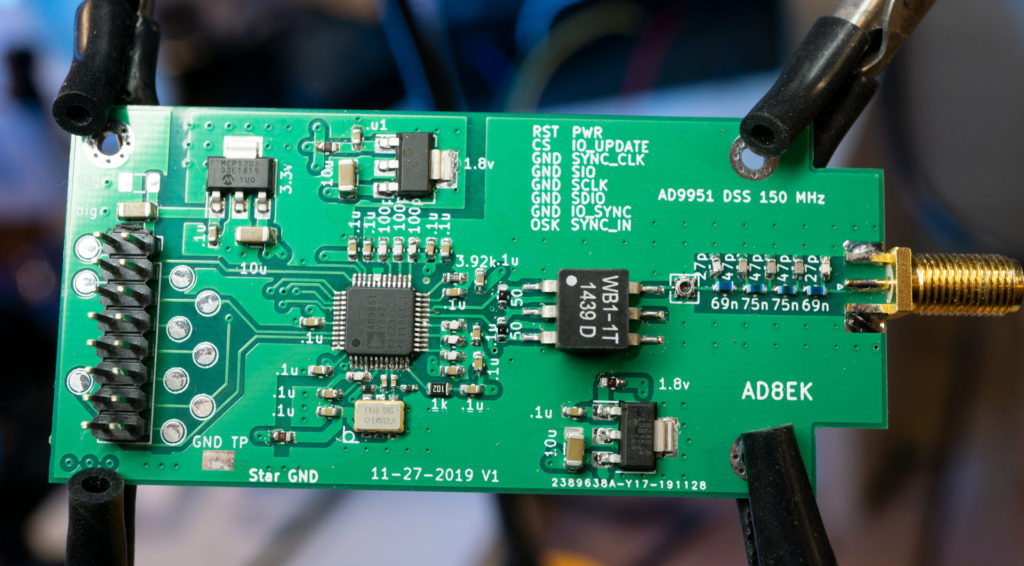

A signal generator made for controlling a dual conversion HF front-end and for making IP3 measurements. Here are some specs:

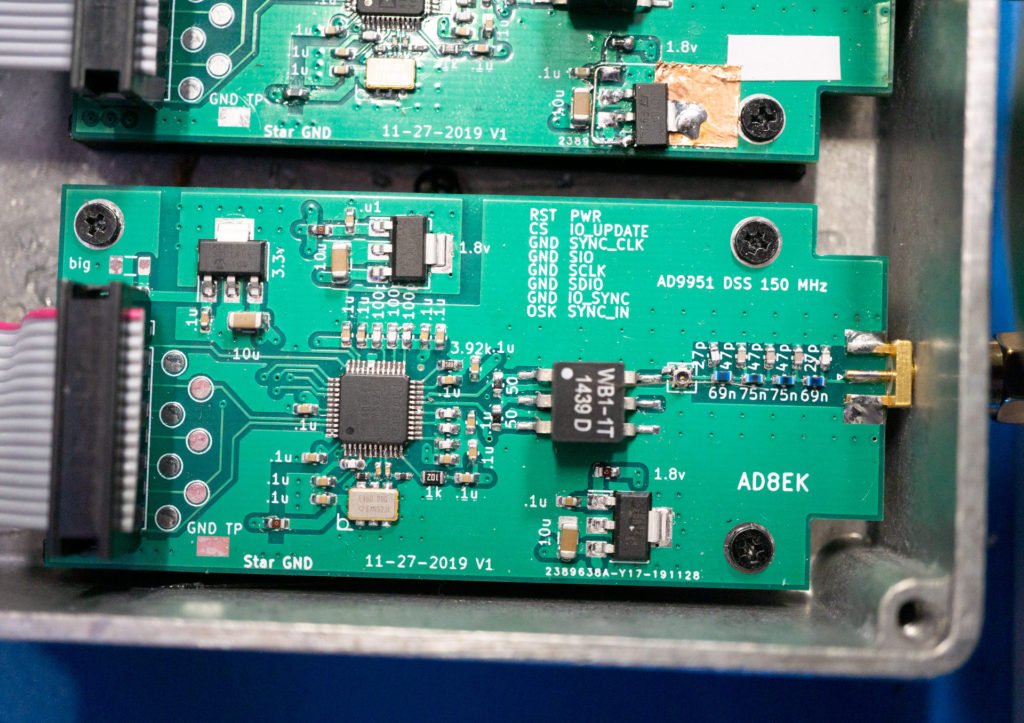

The generator is made up of a bunch of stuff I’ve been playing with. There are two AD9951 DDS chips for synthesizing signals (see below). There is a 300 MHz Atmel M7 chip on a board my dad and I built last year. The display is a 3.5″ Enhanced Nextion screen. And everything else I bought on Amazon or eBay.

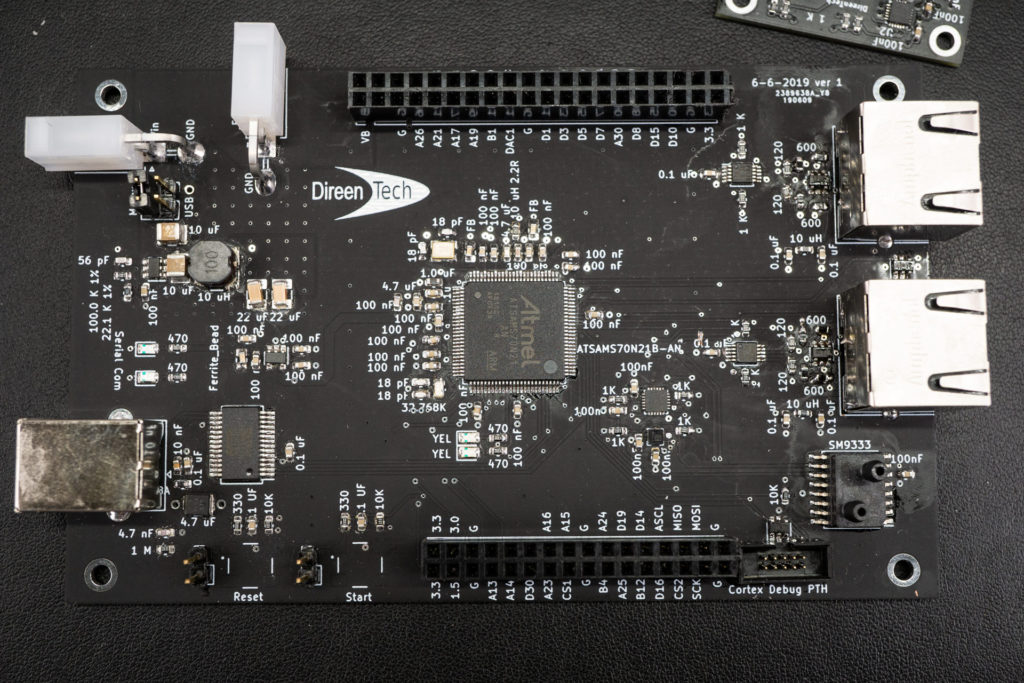

Here is the control board containing the Atmel SAMS70 chip. You may notice the poor soldering job. This is because I did it myself. We designed the board for a variety of projects, which is why there are a couple ports for hats we can add onto the board. This board has been a lot of fun to develop.

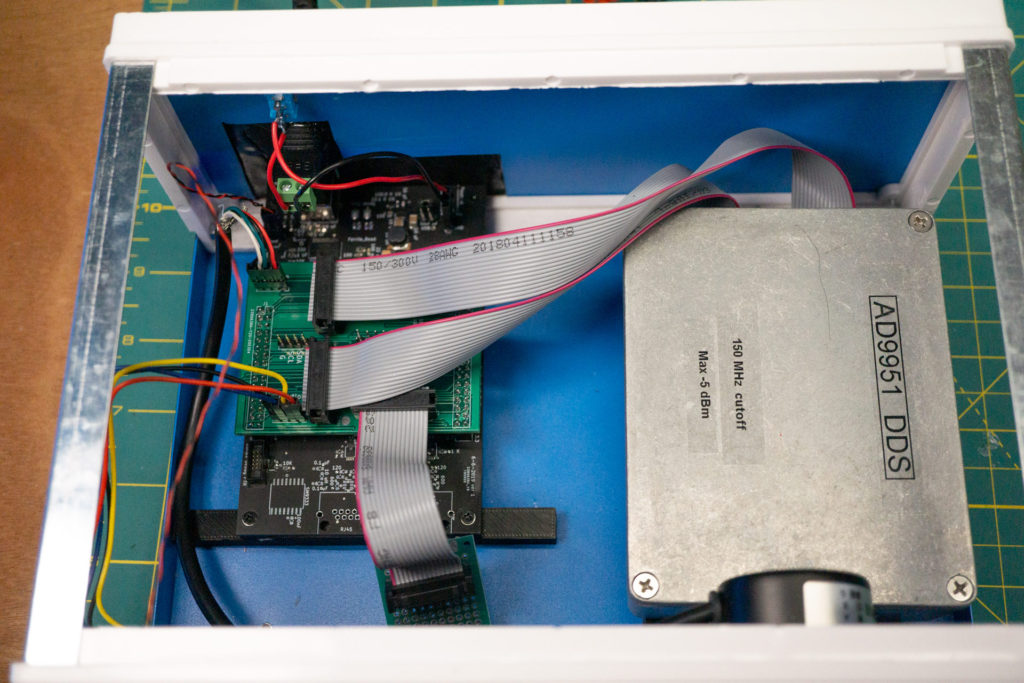

Below is a picture of the control board and the AD9951s placed within a cheap metal box from Amazon. The aluminum box on the right containing the DDS modules was also bought on Amazon. I really like these little boxes for RF projects. Unfortunately, I didn’t put any filter on the ports of the DDS circuit boards so noise creeps out onto the ribbon cable 😐

Inside the aluminum box I screwed the DDS modules into 3D printed stands that are glued to the aluminum bottom. This makes it easy to get the modules in and out for servicing.

If you haven’t used a Nextion display in one of your projects yet, DO IT. It’s the easiest way to make a nice looking users interface (touch included) without having to write a mountain of code. The reason my display doesn’t look good (see below) is that my brother didn’t help. You can get an idea of how it should have looked if you visit his blog within this domain (http://www.direenworks.com). The particular Nextion display I used was a 3.5″ Enhanced version found on Amazon. I 3D printed a holder for it, some buttons, and rotary encoders, which was a lot easier and cleaner to do than just cutting places within the cheap metal box.

I made two pages for the display. The page shown above is for controlling an HF front-end. The first NCO1 frequency is used to mix a signal up to a first IF and the second NCO2 is used to mix down to a second IF. The frequency at the bottom is the tuned frequency I’m interested in. I wanted this level of control so that I could play with different IF frequencies.

The second page is for controlling two tones at a time (see below). This is useful for IP3 measurements (measuring linearity of devices). The two DDS can be controlled independently or together and I can control their output power.

Here is a picture of the signal generator being used to measure OIP3. The device under test is a PGA-103 gain block and I measured OIP3 to be 34 dB. This was nice, because that’s what the datasheet said it should be. The controls of the signal generator make it really easy to choose frequencies I’m interested in and scrub through a reasonable amount of power levels.

I’m happy with this project. I now have a nice tool for generating a couple frequencies in the HF and VHF bands. I’m not sure if it was the most economical route to get what I wanted. I think all in all I spend between $250 and $350 to make it. But, I wanted to develop these pieces so I can use them in other radio projects. Fun stuff.

If you made it all the way to the bottom of this post, thanks for hanging out!

73

Honestly, I wish I got the Fluke 87v. I thought I would like the extra screen size, but the time it takes to boot up is a little annoying. It’s also quite large. Usually I reach for my Fluke 179 unless I need the extra resolution for capacitance or resistance measurements. Still like it though! I just wish it didn’t have to boot for a few seconds every time I want to use it.